Types of Dryers and Vent Length Requirements

To learn why dryer vent length matters, skip ahead to the Types of Vents and Dryer Vent Fire Risks sections at the bottom of this article, but until then, lets learn a little about different types of energy sources, dryers, vents, and general maintenance of a dryer.

Energy Sources:

There are two energy sources for a laundry drying appliance. Those sources are either gas or electric. Gas dryers work by burning gas and using the heat from the flame to warm the air inside the tumbler which dries the laundry. Electric dryers work by heating an electric element to warm the air in the tumbler.

Gas dryers use a flame to heat the air, but since the it is not an open flame, gas dryers have any added risk of causing house fires compared to electric dryers. The risk associated with house fires is caused dryer lint getting trapped and excess heat building up. A properly maintained dryer and vent system is the best way to reduce the likelihood of a fire.

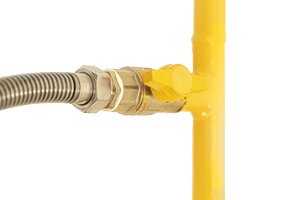

Gas dryers are more expensive than electric dryers and there may be an additional cost for installation as a professional plumber may have to perform additional tasks to properly connect the dryer to the gas line. Gas dryers can be powered with natural gas or liquid propane, but the dryer needs to be properly ported for either gas.

The price of an electric dryer is less expensive than a gas dryer, but typically electric dryers are significantly more expensive to operate as the amount of heat produced by electricity is less per dollar than gas.

British Thermal Units

British Thermal Units or Btu are a unit of measure to describe heat. One Btu is the amount of heat needed to raise one pound of water by one degree Fahrenheit. Electricity produces 3,412 Btu with 1 kilowatt-hour, Liquid Propane produces 2,516 Btu with 1 cubic foot, and Natural Gas produces 1,037 Btu with 1 cubic foot. The easiest way to understand these number is to compare their market prices per Btu.

The energy cost comparison data that we are using was derived from the U.S. Energy Information Administration as of November 2021. Electricity averaged $0.1399 per kWh ($0.000041 per Btu), Liquid Propane averaged $0.0732 per cubic foot ($0.000029 per Btu), and Natural Gas averaged $0.0209 per cubic foot (0.000020 per Btu).

What this data shows is that an average American household could have an annual utility bill of $430.50 for an electric dryer, $304.50 for a liquid propane dryer, and $210.00 for a natural gas dryer. This data shows that although a gas dryer may be the most expensive to purchase and install, the cost savings over the life of the appliance make it the least expensive drying option.

Why Dryers Need Heat

While drying your clothes the dryer is adding heat, passing air over the garments, and removing the humid air. To understand how adding low humidity air, adding heat, and removing high humidity air from the dryer results in dry clothes we must understand more about water at a molecular level.

Water molecules are constantly trying to reach an equilibrium in their environment between evaporation and condensation. This can be seen as fog outside or steam on the bathroom mirror. The heat produced by the dryer pushes the balance of the water molecules towards evaporation, but if the humidity in the air was not removed, then the clothes would never fully dry. This is because a significant amount of evaporative moisture would be trapped in the air and thus a significant amount of moisture would also be trapped in the garment. You may have noticed this when the dryer has been running for a while, the lint trap is full and then the door is opened which causes warm moist air to hit your face. Then you touch your clothes, and they are still damp because an equal or greater amount of moisture that hit your face is still in your clothes.

If all the humidity in the air could be removed, then the equilibrium between evaporation and condensation would be unbalance which would cause more evaporation to occur. As the process of removing humid air repeats, the water molecules are taken away from the garment to the point that your laundry is dry.

Two common problems that reduce the effectiveness of the dryer are not cleaning the lint trap before every load and putting too many clothes in the dryer. If the lint trap is full, the humid air can not easily escape which at the very least will result in slower drying times and at worst will completely stop the drying process. If too many clothes are added to the dryer, the water molecules will become trapped between the layers of clothing and will not be able to effectively evaporate resulting in damp laundry. If the humidity in the air cannot be effectively removed or if the dryer is overly packed with laundry, adding more heat will not improve drying times, but instead may result in damaged garments.

Dryer Venting Options

Landry drying appliances can be vented or ventless. A vented clothes dryer takes the warm humid air and pushes it to the exterior of the home. A ventless dryer will extract the water vapor from the warm humid air using a condenser.

Vented dryers are the most common types of dryers because of their price. Vented dryers require a dryer vent to extend to the exterior of the house from the laundry room. The benefit of a vented dryer is that the dryer is expelling both the hot air and the moisture which keeps the laundry room cooler.

Ventless dryers have no special ventilation requirements and can be installed almost anywhere in the home depending on the dryer.

Ventless dryers are becoming more popular as many modern homes are becoming very airtight and the flow of air into and out of the house is being controlled by an Energy Recovery Ventilator (ERV). A ventless dryer allows the home to maintain energy standards by not exhausting the homes conditioned air out of the house through a dryer vent.

Types of Vents

There are several types of vents that could be attached to the dryer which may include aluminum foil duct, semi-rigid metal duct, rigid metal duct, slim duct, plastic duct, and vinyl duct. The main consideration when installing duct work for a dryer is to limit the amount of turbulence that air will encounter while traveling through the duct. Small amounts of lint will bypass the lint trap and travel down the duct, but if the air is too turbulent then the lint will not be expelled from the vent and over time the vent could get clogged with lint which can be a significant fire risk.

The guideline for vent length is a maximum distance of 35 feet subtract 2.5 feet for every 45° bend and subtract 5 feet for every 90° bend. There are rules governing the size, shape, connection methods, and terminations of dryer vents, and as an inspection company we rarely see every rule followed.

Since each dryer vent bend subtracts length from the allowable 35’ maximum, some dryers have used their allotted length before the vent has gotten up the wall from the basement. When a dryer vent is too long it is possible to add an inline dryer vent booster. This little fan can add additional pushing power, improve the flow of air, and keep dryer lint from building up inside the dryer vent. One downside to inline dryer vent boosters is that cleaning the dryer vent can be more complicated because there is no longer an ability to push a brush from one end of the vent to the other without obstructions.

One of the most common issues that we find with dryer vents after excessive length is improper termination of the vent to the exterior. To prevent pests from enter the home we would prefer to have screens on every vent, but a screen would reduce air flow and catch lint which would increase the risk of fire. A compromise is to install a vent that has a grill cover to prevent large pests such as squirls and chipmucks from enter the home without restricting the flow of air or collecting dryer lint.

Dryer Lint Fire Risks

Dryer lint is very combustible and can even be used as a fire starter when camping. The fire triangle shows us that we need to have a fuel source, fresh air, and heat to start and maintain a fire. If the dryer vent is clogged your laundry will not dry effectively. Many modern dryers have moisture sensors which will turn off the heat when the laundry is dry, but if your clothes are not drying properly, you may bypass these sensors, do a long timed drying cycle, and add more heat. The drying cycle will continue even though your laundry is dry, and the vented air will become very dry and very hot which could be enough to cause a dryer vent fire.

To reduce the likelihood of a fire, use the sensor drying cycles on your dryer and remove fuel sources such as lint. The lint trap should be cleaned before every new load of laundry, lint around the dryer should be removed as it builds up, and the dryer vent should be cleaned once every year.

Dryer vents can be cleaned by professionals or can be done by the homeowner using a special vent brush. Dryer vent cleaning kits can be purchased and attached to a standard drill. The rotary action of the brush while pushing the brush from one end of the vent to the other can ensure that lint is released from the walls of the vent duct and completely removed from the vent duct.

In general the steps of cleaning a dryer vent include turning off the gas or disconnecting the power, removing the vent duct from the back of the dryer, removing the exterior vent hood termination from the dryer vent duct, vacuuming the dryer duct vent port at the rear of the dryer, using the rotary duct cleaning brush to clean the length of the duct until the brush exits the far end of the vent, vacuuming up the lint around the dryer, and then reassembling and testing the system.

Performing this simple maintenance item can reduce energy costs, reduce drying times, and reduce the risk of dryer vent fires.