Oxygen Permeable Pipe Is Damaging Your Boiler

If you don’t have a hydronic system and don’t want to learn about what I just described, then please check out our other videos or blog posts, but if you are interested in a story about finding balance, social isolation, making friends, destructive behavior, and ultimately a rift that couldn’t be bridged then you are going to want to stick around for this one.

Before we go down the rabbit hole of this three-part video series, lets define what we are talking about while we are still standing at the entrance of this rabbit hole...

A hydronic system is a heating system that heats a liquid and circulates it through a loop such as an in-floor radiant heating system or heated driveway. When oxygen diffusion is not controlled the metal components such as the boiler, circulators, and valves will rust and fail prematurely at a great expense.

Ok, spoiler alert maybe it isn’t as dramatic as that; Oxygen wants to find balanced between the inside and outside of heating pipes, Iron Oxide can stop new oxygen from meeting new iron, oxygen wants to make friends with iron, Oxygen and iron’s friendship results the destruction of the place they call home, and ultimately oxygen and iron are forever separated by a stainless-steel heat exchanger…

Now that we know the whole story, let’s try to understand it a little further. To make sure we are on the same page, lets define a few words in the way we’ll be using them in these videos:

Permeable means a material that allows a gas to pass through it

Hydronic is a type of heating system that heats a liquid and circulates it to heat a home. This might include an in-floor heating system, heated driveway, or a hot water tank for your hot showers.

Diffusion is the movement of a gas from an area of higher concentration to an area of lower concentration, eventually finding a balance or equilibrium

Oxide is a chemical compound made of Oxygen and Iron and is also commonly known as rust

Ferrous is a material that contains Iron

Now that we are on the same page lets start figuring out if your Hydronic Heating system is at risk.

There is oxygen all around us, but when we try to add or takeaway oxygen it never seems to last. If you fill up a balloon with air it will eventually go flat and if you try to get all the air out of a bag of food, it will eventually fill back up. The reason this happens is because most materials are oxygen permeable which means that oxygen can pass through the material. Some materials are better at stopping oxygen from diffusing through them and others are worse. Think about blowing air into a balloon and how the balloon traps the air inside. Eventually the air will be able to escape, but the balloon does a good job of holding the air back. Now think about doing the same thing but blowing air into a sock… the sock does a bad job of holding back the air and it will never be able to inflate.

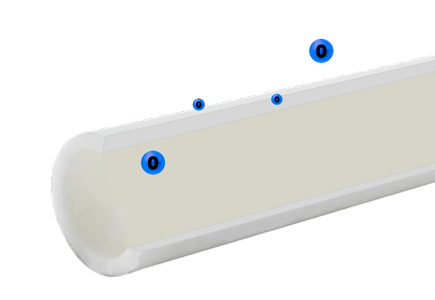

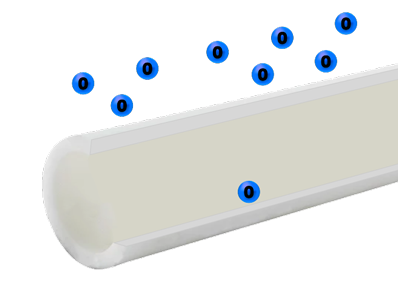

The same thing is happening with the hydronic pipes in your home. If the pipe is good at holding back oxygen, then there can be different amounts of oxygen inside and outside of the pipe. This type of pipe is called oxygen barrier because the oxygen can’t pass through the pipe.

If the pipe material is bad at holding back air, the oxygen from outside the pipe will find its way into the pipe and vice versa meaning that there can’t be different amounts of oxygen inside and outside of the pipe. This type of pipe is called oxygen permeable because the oxygen can pass through the pipe.

When a closed loop hydronic system is working properly heat is transported using a liquid that is circulated through a pipe loop and back to the heat source, and the small amounts of oxygen trapped inside the pipes will start to corrode the ferrous materials which are materials that contain iron. These Ferrous materials can be found in cast iron boilers, steel circulator pipes, metal valves, and so on. The result of this corrosion is rust and the more oxygen that is present in the system, the more rust there will be. The amount of oxygen in the system has nothing to do with high or low internal pressures of the pipes, but instead the oxygen permeability of the pipes.

With this said, corrosion is expected and in a closed loop system the limited amount of oxygen trapped inside the pipes will create a fine layer of rust known as Iron Oxide. This oxide will form a protective layer of rust on the ferrous parts of the system preventing stray oxygen atoms from causing ongoing corrosion. Iron oxide is created any time three oxygen atoms bind with two iron atoms. There are 16 types of oxides that could be produced, but we will just call this type of oxide: rust. And, if no additional oxygen is added to the system, all the oxygen atoms in the system will find an Iron atom and create rust together. The layer of sacrificial iron oxide is expected and will protect the rest of the ferrous materials by absorbing all the oxygen atoms in the system and converting them into rust until the closed system is completely oxygen free. If the system is drained for maintenance the drained water will be rusty and disgusting, but that is expected. When the system is refilled, the new oxygen atoms will go to work rusting away the iron until all the oxygen in the system is depleted yet again.

Unfortunately, if oxygen is free to enter the “closed loop system” through a loose fitting or oxygen permeable pipe, the corrosion of the ferrous materials won’t stop until all the iron has rusted away causing the system to fail catastrophically. The corrosion is exacerbated with higher temperatures which is why you see more oxygen permeable issues in heated driveways and staple-up residential in-floor systems because those systems need more heat to produce the desired effect when compared to other radiant systems. As the system is rusting away, the liquid inside the pipes will turn into a slurry of rust that will be constantly circulating around the system bumping into valves, pumps, and heat exchangers slowly wearing the components away until they no longer function as intended. Eventually the boiler, pumps, expansion tank, or valves will fail, or the system will become clogged. At that point action needs to be taken.

I

This is part two of a three-part video series discussing radiant heating systems and how oxygen permeable pipe can cause your system to fail prematurely. Here is the one sentence recap from video one: Some homes had hydronic heating systems such as in-floor radiant heat, or heated driveways that were installed with oxygen permeable pipe that allowed oxygen to defuse into the closed loop hydronic system and caused the components of the system to rust away until nothing was left except for a prematurely failed system that needed replaced at great expense.

There are many different types of pipes that have been used for hydronic systems, but currently the most popular type of pipe being installed is PEX. PEX is not a name brand, it is a descriptor for the type of plastic and its manufacturing process. PEX is short for Cross-Linked Polyethylene, and there are several different types of PEX that have unique variations to their manufacturing process. To create the crosslinking of the polyethylene molecules, Pex-A uses a melting process, Pex-B uses a steam bath, and Pex-C uses an electron beam. There are pros and cons to each resulting type of PEX, and there are many different manufactures that produce subtle variations. To confuse things even further some people will refer to the type of Pex by the manufacturer who produces it such as Wirsbo. Wirsbo was well known for producing PEX-A and their company name was often used as the preferred way to describe the type of pipe being used. Wirsbo made many other products, but to confuse things even further, Wirsbo is now Uponor, but you still hear people saying Wirsbo on the jobsite and to make things worse Uponor has a hydronic specific pipe that is branded with the Wirsbo name. So, instead of saying Pex-A, Pex-B, Pex-C, Wirsbo, or Uponor, we are just going to say Pex from this point forward.

Non-Barrier PEX is used as an alternative to Copper and CPVC rigid piping for residential and commercial potable and non-potable water plumbing. Non-Barrier PEX has a high resistance to chlorine which is why it is so frequently used for everyday hot and cold-water supplies which are known as open loop systems. These pipes can often be identified by their matte surface

Oxygen Barrier PEX is the same as the previously listed PEX, but it has an oxygen barrier that prevents the diffusion of oxygen molecules into the water through the walls of the pipe. The layer is made of Ethylene Vinyl Alcohol or EVOH which is also found in food packaging to help retain freshness. This prevents the corrosion of cast iron components such as circulator pumps, air purgers, fill valves, boiler heating elements, and heat exchangers just to name a few. This type of pipe is primarily used for hot water hydronic heating such as baseboard/radiator heating, fan foils, radiant floor heating, and snow melting applications which are known as closed loop systems. These pipes can often be identified by their glossy surface. If a PEX pipe has an oxygen barrier it may also have DIN 4726 printed on the pipe.

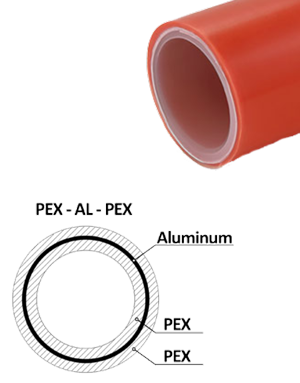

PEX-AL-PEX has an internal layer of aluminum sandwiched between two layers of PEX. The aluminum layer creates an oxygen diffusion barrier without the need for additional coatings. When the pipe is bent the pipe will stay in the bent position allowing one person to install the pipe more easily by themselves. The aluminum also increases the pressure rating for the PEX Pipe.

To help with the identification of plumbing pipes, PEX may be colored red for hot, blue for cold, or white for neutral. The color has no bearing on the performance or use of the pipe, but instead it is a personal preference by the plumber to choose what color to identify the plumbing with. The color orange is usually reserved for PEX-AL-PEX pipes.

With all these different PEX pipe options it is very possible that an installer may accidentally or intentionally install a non-barrier PEX pipe to try and save money. If non-barrier PEX was accidentally installed, hopefully they also accidentally installed non-ferrous parts, so they won’t rust, but that seems unlikely. Sometimes when using tens of thousands of feet of pipe for a house or driveway an installer may intentionally use a non-barrier pipe to save the homeowner a significant amount of money even when accounting for the added cost of non-ferrous materials such as stainless-steel, copper, or brass. This type of installation is completely acceptable, but the homeowner needs to be aware that all future repairs must be done with non-ferrous materials.

PEX is considered an appropriate pipe for hydronic systems, but there are several types of pipes that were used for hydronic systems that ended in lawsuits and the banning the product from use nationwide. One of the worst offenders was Polybutylene. Poly-Butylene Pipe was a gray plastic pipe used for domestic water and hydronic systems from 1978 to 1995. Poly-B didn’t have and oxygen barrier for hydronic systems until later, but in the mid 1980’s the Poly-B pipes started to crack and leak, and it was soon discovered that there were issues with fittings and deterioration of the plastic pipe from heat and chlorine. Since hydronic systems create heat and drinking water can contain chlorine the Poly-B hydronic systems could fail in as little as 3 years vs a typical 25-year life expectancy. In 1995 a class-action lawsuit was filed which settled for $950 million.

A product that had a similarly poor track record was Entran II. Entran II did not have an oxygen Barrier, but Entran III did, however, oxygen permeability was the least important issue found with these pipes. Entran II was a rubber hose produced by the Goodyear Tire Company and was used for radiant in-floor heating and snow melt systems installed from 1989-1994. During this time, a plasticizer used to keep the rubber flexible would leach out of the rubber when exposed to heat which would cause the rubber to harden. This resulted in the failure of the system and damage to the house when the pipes would rupture and the liquid inside the pipes would seep into the walls and floors of the house. In 2004 Goodyear settled a class action lawsuit for a minimum of $196 million to a maximum of $236 million. Goodyear also had an “improved” product called Entran III which was used for radiant in-floor heating and snow melt systems installed from 1992-1996. Entran III has had many issues, but the United States Court of Appeals for the District of Colorado ruled in 2016 that a product is not considered defective if 10 years has passed since it was first sold. Even though that product had an expected useful life of greater than 40 years, was marketed and sold with that expectation, and the methods of installation made repair or replacement impractical, which are all things that Goodyear affirmed in court. But the court affirmed that Entran III was not defective, and Goodyear was not liable.

As you can see having the wrong type of pipe installed can easily lead to expensive lawsuits and prohibitively expensive remedies, so what is a homeowner to do?

This is the third and final video in this series about oxygen permeable pipe, and to recap, a hydronic system is a heating system that heats a liquid and circulates it through a loop such as an in-floor radiant heating system or a heated driveway. When oxygen diffusion is not controlled the metal components of the system will rust and fail prematurely. Oxygen Barrier pipe can be identified by a shiny gloss surface, or the labels; DIN 4726 or PEX-AL-PEX. If the pipe has a matte surface, looks like a rubber hose, or if it is gray in color, then you might have a bad pipe.

Now, let’s talk possible solutions.

If the bad type of pipe that you have is Entran II, Entran III, or Polybutylene the risk of pipe failure which would result in damage to your house may push you toward pricing out a retrofit solution. Some systems can be retrofit using hydronic baseboard heating, in-ceiling hydronic heating, or staple up in-floor heating. These types of retrofit options are often expensive but protecting your home and valued personal items from leaking pipes is priceless.

If the bad type of pipe that you have is a non-barrier pipe there are several remedies that range in price from free for now, to very expensive.

First and foremost, with any of these issues, you can choose to do nothing, that would be a “free for now” option. There is always a knee jerk reaction when issues show up in inspection reports that something must be done but being identified in the report doesn’t mean that you need to do anything. Some systems that should have failed 10 years ago are still running strong, so you can wait until the system fails, you can budget for a new system and change it when you have the funding, or you can fix it now. Even when the system fails you may choose to replace the parts with the least expensive option instead of installing a more expensive non-ferrous option such as stainless steel, copper, or brass. Ultimately the less expensive ferrous system will still fail prematurely but replacing it again may still be less expensive than a complete retrofit.

So, what is the next least expensive option from doing nothing? Chemicals are relatively inexpensive, and they can be used to neutralize the oxygen in the system. These chemicals will need to be monitored annually and adjusted by a professional otherwise the chemicals could cause more harm than good, but they are a viable option if you are trying to prolong your current system.

The next option’s price is considered middle of the road for this type of repair and is often the preferred method. The installation of a heat exchanger will separate the parts of your system that can rust from the parts of your system that introduce oxygen. Stainless steel won’t rust and is perfect for this application. There are three common types of heat exchangers. Shell and Tube, Shell and Coil, and Flat Plate. Shell and Tube heat exchangers are rarely used in residential settings because they are very large, are prone to fouling deposits, and suffer from parasitic heat loss which means heat lost to the room. Shell and coil heat exchangers are most used to heat domestic hot water and not to heat the house. Flat plate heat exchangers are the most common type of heat exchangers, and they can be classified as brazed plate heat exchangers or plate and frame heat exchangers. Brazed plate heat exchangers, BPHEs, are the industry standard for residential systems as they have no moving parts, no rubber seals or gaskets, a compact size, self-cleaning turbulent flows, and up to 95% of the BPHEs materials are used to transfer heat. The main takeaway from this is that a stainless-steel heat exchanger will keep the liquid that is in the oxygen permeable pipes physically separated from the liquid in the boiler loop which means the issue of oxygen diffusion corrosion has been solved without needing to replace any pipes.

The most expensive option is to install a new non-ferrous boiler and components, but if your boiler is already failing or past its design life, this may be the most practical solution. If you are upgrading your boiler to a unit that has a stainless steel or copper heat exchanger, you will also want to upgrade the valves and circulators to a non-ferrous material such as stainless steel, copper, or brass. Most indirect side arm water heaters are already stainless steel because they interact with the open loop drinking water that is highly oxygenated, so there is normally no need to upgrade this component.

We have yet to inspect a “Perfect” house, and we see a significant number of houses in our area that have oxygen permeable pipe and we want to let you know that oxygen permeable pipe is not a deal breaker, it is just something to consider when buying a house similarly to how you may consider the expense of updating a kitchen or a bathroom. However, I understand it isn’t as much fun to plan a heating system upgrade as it is to plan a kitchen remodel.

Hopefully, we provided you with some educational material, but if you have any additional questions or would like to schedule a home inspection, please visit TwoMooseHomeInspections.com, thanks for reading, have a wonderful day!